3 Things to Consider Before Launching Your Next Pharma or Co-Pay Card Program

If you’re in the market for co-pay cards or pharmacy discount cards that you want delivered to doctors’ offices, consumers or pharmacies, you’re going to need a complete range of services to make it happen. Ideally, you’ll want all of these solutions (printing, fulfillment, etc.) to come from a single vendor or source of contact. Why? To make your job easier, of course, and to also ensure accuracy of your product. After all, who wants a card that doesn’t work!? So in your search for this “all-in-one” vendor, let’s take a look at what you should consider before you start your next card marketing program.

Print & Design

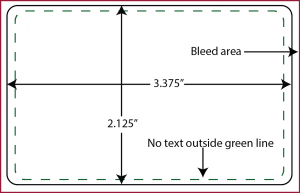

All card-based programs start with a design, or artwork if you will. Unlike other forms of printed collateral, cards are a bit different when it come s to design layout. Therefore, you’ll need a printer that can advise you on font size, location, print characteristics, and how much white space to leave around the pre-printed information for die-cutting and personalization. You’ll also need advice on selecting the appropriate thickness of your cards, which typically runs from 15mil to 30mil (which is the thickness of a standard credit card). And then there is finishing for the cards. Do you want laminated or UV coated plastic? How do these features affect cost and delivery times? Finally, credit card-sized products, which in our industry are called CR80s after an ISO standard, are only the beginning of your options. There are also cards with one or two keytags, double cards, triple cards and more, depending upon how your product is going to be used.

s to design layout. Therefore, you’ll need a printer that can advise you on font size, location, print characteristics, and how much white space to leave around the pre-printed information for die-cutting and personalization. You’ll also need advice on selecting the appropriate thickness of your cards, which typically runs from 15mil to 30mil (which is the thickness of a standard credit card). And then there is finishing for the cards. Do you want laminated or UV coated plastic? How do these features affect cost and delivery times? Finally, credit card-sized products, which in our industry are called CR80s after an ISO standard, are only the beginning of your options. There are also cards with one or two keytags, double cards, triple cards and more, depending upon how your product is going to be used.

Personalization | Serialization

When you add numbers only to a card it’s called serialization. Add names, and its called personalization. What kind of personalization fits your project will depend on how/if you want to track card usage. How the card is serialized or personalized depends on the material. Most often, cards are printed with inkjet technology, which works great on a laminated PVC card. However, for UV coated cards, you need a special surface that is “writable.” Most experienced card printers will know the difference. The typical card is printed with Drop-on-Demand (DOD) ink, which is specially formulated to work with these coated substrates. It also provides a neat and clean font that can easily be read. This has been a great advancement in the printing world since the use of traditional MEK inks.

that can easily be read. This has been a great advancement in the printing world since the use of traditional MEK inks.

Packaging

There is a world of solutions when it comes to card packaging. Do you need a carrier or wrap to go with your card? If so, what weight and finish of paper are you looking for? Do you require a sealed product that folds over, or just a standard hang tag with a card attached (like a gift card)? Perhaps you’d like the card packaged into bulk packs for easy distribution to doctors’ offices. In that case, you’ll want to look for a solution that won’t break the bank. Finally, you might need an online fulfillment option. You’ll want to contact a vendor that is capable of integrating a web-based ordering system and a responsive mailing solution.

Finally, be sure your solution is run by a HIPAA compliant vendor. Nothing could be worse than a data or information breach caused by relaxed vendor production procedures. Play it safe. Play it smart. Get the program protection you need to ensure flawless execution.